In the fast‑moving world of robotics automation, selecting the right gear motor is a critical decision that can make or break a project. From pick‑and‑place workcells in electronics manufacturing to mobile robots navigating warehouses, the motor must deliver the correct combination of torque, speed, and reliability. This article walks through the fundamentals of gear motor selection: how to match power and speed ratios, evaluate performance metrics, and choose the best motor for your upgrade. Whether you’re a seasoned engineer or a beginner stepping into robotics, these guidelines will help you make informed decisions and keep your automation running smoothly.

Before diving into motor specs, identify the mechanical tasks the robot will perform. Key questions include:

Answering these questions transforms vague goals into quantifiable parameters that guide motor selection.

A gear motor is essentially an electric motor paired with a gearbox. The gearbox multiplies torque while reducing speed, or vice versa, depending on its configuration. The fundamental relationship among torque (T), speed (N), and power (P) is:

P (W) = T (Nm) × 2π × N (rad/s)

In simpler terms, power is the product of torque and speed. If your robot needs high torque at low speed (common for lifting heavy objects), you’ll choose a high gear ratio. Conversely, if quick motion is required, a low gear ratio or direct‑drive motor may be preferable.

Electric motors are rated for continuous power and peak power. The continuous power rating indicates the maximum power the motor can handle without overheating over an extended period. Peak power is the short‑term surge capability during starts, stops, or sudden load changes.

When selecting a motor:

Example: If your robot pulls a 5‑kg load at 0.5 m/s on a flat surface, calculate the required torque using the formula T = F × r, where F is force and r is the radius of the drive shaft. Then use the torque to find the required power at the desired speed.

The gear ratio is the ratio of the input shaft speed (motor speed) to the output shaft speed (robot movement). It is calculated as:

Gear Ratio = N_input / N_output

Choosing the correct ratio ensures that the motor’s speed is reduced to a level suitable for the robot’s mechanical action, while the torque is increased to meet load demands. A common mistake is selecting a gear ratio that is too high, leading to excessive torque but severely limiting speed, or a ratio that’s too low, making the motor over‑overheat.

Tip: Plot torque and speed curves for a few candidate ratios on the same graph to visually compare their ability to meet your requirements across the full range of motion.

Gearboxes are not 100 % efficient. Energy losses occur due to friction and backlash. Typical efficiencies range from 80 % for spur gears to 95 % for planetary gear sets. A higher efficiency gearbox results in more reliable performance and less heat generation.

Back‑drivability—the ability for the output to move the motor back through the gears—is important if your robot must return to a previous position under load (e.g., a robotic arm that needs to lift an object and then retract). Gearboxes with low backlash and smooth operation are preferable for back‑drivable applications.

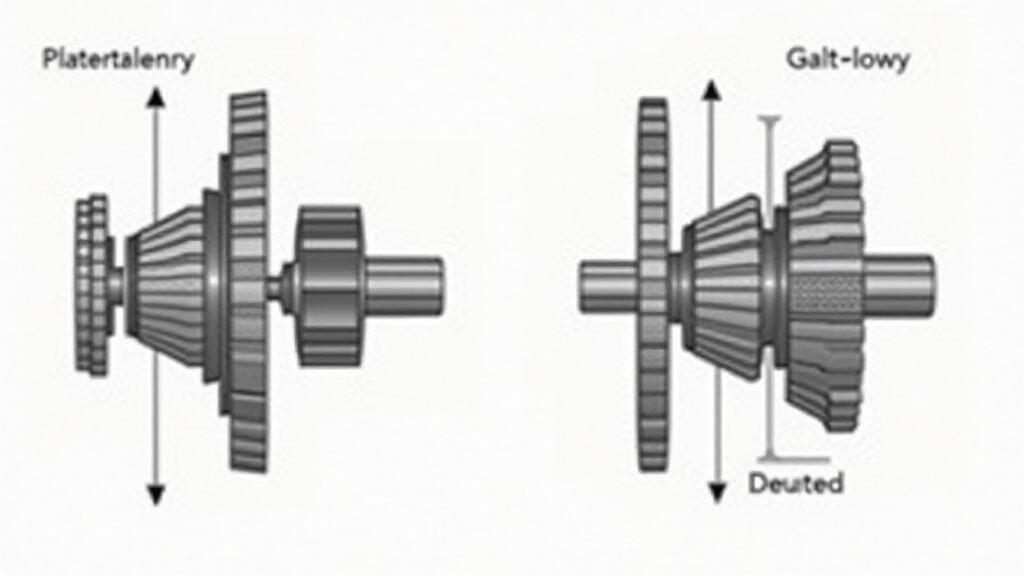

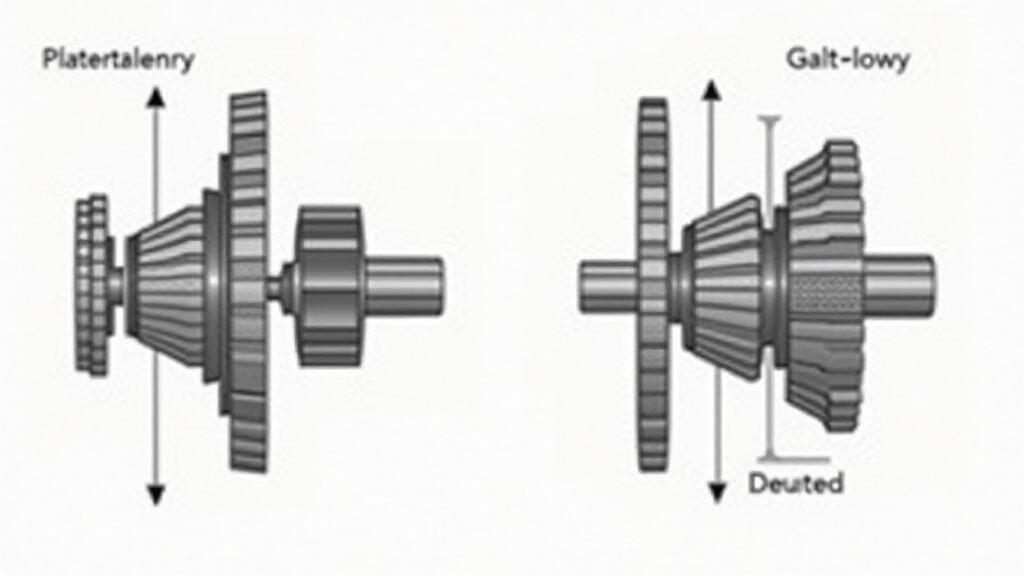

Image Prompt:

This image would help readers visually grasp gearbox efficiency.

Every motor generates heat proportional to its power consumption. Adequate cooling—whether through forced air, liquid cooling, or heat sinks—is essential, especially for high‑power motors in continuous duty cycles. Check the motor’s heat dissipation rate and ambient temperature ratings. If the motor exceeds its thermal limits, it may shut down or suffer reduced lifespan.

Duty cycle is measured as the ratio of operating time to the total cycle time (e.g., 80 % duty cycle means the motor runs for 8 minutes every 10 minutes). Selecting a motor with a duty cycle that meets or exceeds your operation schedule prevents over‑stress and extends reliability.

Modern robotics often rely on precise control of torque, speed, and position. Verify that the motor’s control interface (e.g., PWM, analog voltage, field‑modulated control) aligns with your existing PLCs, drives, or custom electronics. Look for motors that natively support standard communication protocols like CANopen or EtherCAT if you plan to integrate into a broader automation network.

Additionally, consider the motor’s backlash, stiction, and torque ripple, as these factors affect positioning accuracy—critical for precision tasks like drilling or assembly.

Beyond initial purchase price, evaluate the total cost of ownership: durability, maintenance intervals, and part availability. A motor that lasts 5 years with minimal servicing can be cheaper overall than a low‑cost motor that fails after a year. Check the supplier’s documentation, technical support, and warranty terms.

When upgrading a robotic system, always buy in compatibility with existing components (mounting brackets, shaft diameters, cable sizes) to reduce retrofitting costs.

Selecting the right gear motor for robotics automation upgrades is a blend of physics, engineering judgment, and practical logistics. By matching power and speed ratios carefully, accounting for gearbox efficiency, thermal limits, and control interoperability, you can ensure your robot operates reliably, responsively, and safely. As factories move toward greater autonomy and flexible manufacturing, the importance of a well‑chosen gear motor only grows—paving the way for faster production cycles, lower energy consumption, and upgradable systems that stay future‑proof.

Armed with these guidelines, you’re ready to evaluate motor specifications, run simple calculations, and pick the perfect gear motor for your next robotics automatic upgrade. Happy engineering!

Leave A Reply

Your email address will not be published. Required fiels are marked